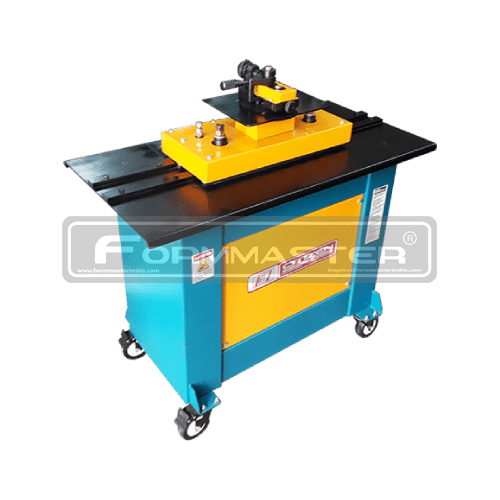

Model : LFMC20 / LFMC18 / LFMC18 (6 IN 1) / LFMC16 / LFMC16-T / LFMC14-T

Lock Forming Machine

What is a Lock Forming Machine and its usage and Advantages?

A Lock Forming Machine is a specialized piece of equipment used in the sheet metal forming process to create interlocking seams or locks. These locks are essential for joining pieces of sheet metal together, providing strength and stability to the final product

A Standard Lock Forming Machine can for Pittsburgh Lock Seam Profile, Right Angle Flange Profile, Double Seam (Acme) Joints & Drive Cleat Profile

Usage:

HVAC Systems: Creating ductwork and other components.

Pipe Making: Manufacturing of sheet metal pipe like Flour Mill Pipes, Flue Pipes – Chimney etc

Construction: Forming metal roofing panels and building facades.

Automotive: Manufacturing car parts and components that require precise metal joints

Advantages :

High Precision: Ensures uniform and consistent locks, enhancing the structural integrity of the final product.

Efficiency: Automated features increase production speed and reduce labour costs.

Versatility: Capable of creating various lock types for different applications.

Durability: Produces strong, durable joints that are essential for the longevity of the product

Contact

CITIZEN ENGINEERING WORKS

10, Amar Industrail Estate, Opp. Lathia Rubber Works, Andheri-Kurla Road, Andheri East, Sakinaka, Mumbai – 400 072

details

- +91 98679 60169

- +91 98922 56045

- info@citizenengworks.com